Jointer Plane Review

06 Nov 2022I recently found this big old wooden jointer plane online and decided to buy it. I will convert it into a specialized shooting plane, but for now, I take it apart, tune it, and marvel at the idiosyncrasies of the Soviet manufacturing processes.

I believe the plane had been factory-produced in the 80s, then someone put it into a barn and never used it.

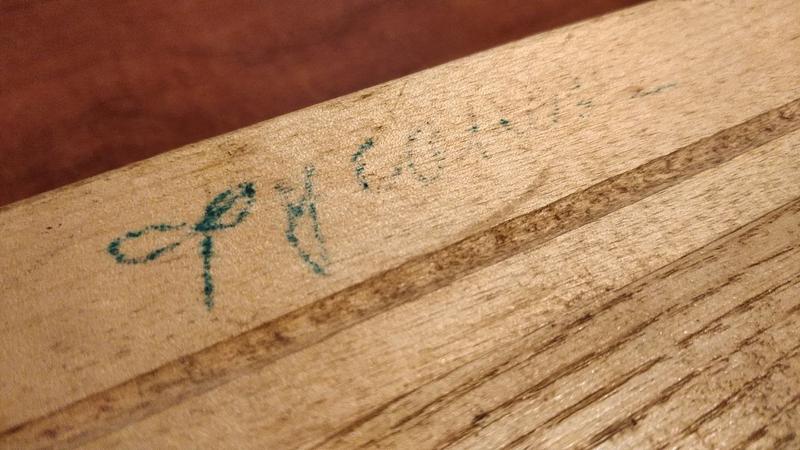

With a crayon, the owner scribbled the word ФУГАНОК on its side, which means "jointer plane". Right, because what if someone mistook it for a different kind of plane (oh, the horror)?

There is even a quality control stamp, proudly applied by Quality Control Operator #2. "Here you go, comrade, this plane conforms to the specification of ГОСТ 14665-77".

Looking at the plane now, I can say it indeed has never been used. The iron is covered in gunk and traces of oiled paper. It is fairly dull. It comes with a chip breaker, which does not fit the iron well - there's a visible gap that will collect all the chips.

At least the blade is made from decent tool steel of the era. It's visibly out of flat, but the heat treatment is good. The blade is harder than my files and after a few strokes on the sharpening stone, the surface is nice and shiny.

The bed of the plane looks pretty rough. I'm sure it was cut by a machine, but the cutter must have been dull, so there is significant tear-out and roughness in all the end-grain faces.

I did not notice it at the first glance, but the bed is a bit skewed. I am not sure if this was intentional, or an accident. Whatever the reason, it would only mean minor complications for the wedge geometry. Which, I must say, the manufacturer solved brilliantly, by making a wedge that simply does not fit.

Either that, or the original wedge is lost, and this wedge is from a different, smaller wooden plane.

The plane comes with one blocky and uncomfortable handle. Looks like they cut it out of a plank, then routed a tiny chamfer on the inside and called it a day.

Interestingly enough, the handle is attached using a machine-cut dovetail. For some reason, the dovetail is off-center.

Looking at the heel of the plane, it becomes obvious that the two boards that the body is constructed from have their own shortcomings. The top board is quartersawn, symmetrical, and it is good. I only wish it were cut further from the center of the log so that the annual rings were flatter. Unfortunately, the lower board, which looks like oak, is not as symmetrical.

As a result, there is a small gap between the boards. It is only a matter of time until this joint fails, so I pop it open with a chisel. The boards separate neatly.

This joint was doomed to fail. Looks like the Homo Sovieticus that produced this plane did not care very much about the finish on the glue surfaces. After all, who's going to see them?

From what I know of PVA glue, it makes a stronger-than-wood connection. The fact that the boards separated so cleanly, makes me suspect there was not enough glue in the joint. Well, it is all for the best, as now I can smooth these boards and glue them back together.

Before this plane makes any shavings, I need to fix a few things. First, I'll flatten and sharpen the iron, and file down the chip breaker until it fits. Then I need to clean up the mating surfaces of the two boards and glue the body back together. I will not skimp on the glue and use every clamp I have to even out the pressure. Then I need to make a new wedge. The sole needs some flattening, of course.

I want to eventually convert this plane to a specialized shooting plane. I'll shape the handle for a more comfortable fit, and shorten the plane. If it works out, I'll have a nice new tool. Otherwise, I'll at least get some old and stable wood for a different project.

DIY Blog

DIY Blog